Stage

M2 internship offer : Engineering granular hydrogel scaffolds through liquid-liquid phase separation for 3D cell culture and tissue engineering

Date de publication

22.10.25

Prise de poste souhaitée

04.01.26

Engineering granular hydrogel scaffolds through liquid-liquid phase separation for 3D cell culture and tissue engineering

Context

Tissue engineering is a rapidly expanding field at the crossroads of biology, engineering, and material science. Its primary objective is to recreate in vitro artificial biological tissues that recapitulate specific functions of organs or organisms. Such engineered tissues not only provide experimental models that more faithfully reflect physiological conditions than conventional cell cultures but also hold significant promise for regenerative medicine, particularly for the repair of damaged tissues. Current approaches largely rely on the assembly of living cells within hydrogel matrices that support their development. The properties of these matrices are critical for cell behavior, necessitating precise control over parameters such as chemical composition, mechanical properties, and structural architecture.

Internship objectives

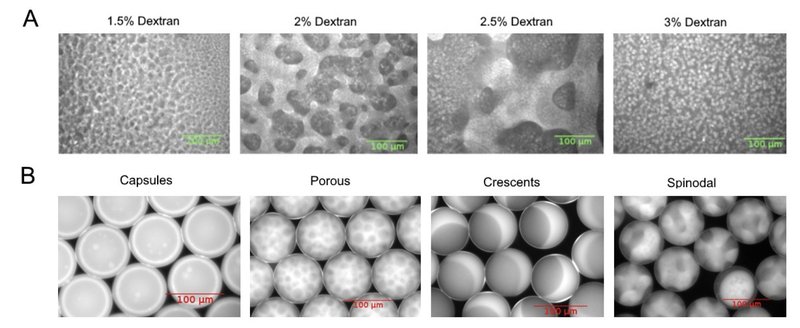

Liquid–liquid phase separation (LLPS) is a physical process in which polymers spontaneously demix into two phases. In tissue engineering, LLPS is increasingly exploited to design biomimetic materials and scaffolds that recapitulate dynamic, compartmentalized microenvironments, thereby enhancing cell signaling, differentiation, and tissue maturation. While this principle has already been demonstrated with synthetic polymer such as PEG1, we aim at transferring it to biopolymers (e.g. GelMA) derived from natural extracellular matrix.

The aim of the internship is to design and develop such materials. A range of parameters will be investigated to achieve fine control of the LLPS process, and the resulting materials will be characterized with respect to their structural and mechanical properties, as well as their biocompatibility and influence on in-vitro cell behavior.

Figure 1: A: LPPS occurs between gelMA (4.5%) and dextran (1.5-3%) leading to the formation of a bicontinuous gel with controlled pore size. Changing the concentration of dextran leads to different architecture: 1.5%: dextran droplets in gelMA, 3%: gelMA droplets in dextran, 2% and 2.5%: bicontinuous environment. B: LPPS occurs in micro droplets generated through microfluidics, resulting in diverse micro architectures.

Hosting team

The team ELiA in LAAS-CNRS has strong expertise in biomaterials, tissue engineering, bioprinting and microfluidics. The team also benefits from an important collaborative network within the Toulouse environment (RESTORE, CRCT, I2MC).

Expected skills

Any knowledge or experience in the fields of bioengineering, biotechnology, tissue engineering, fluid dynamics, thermodynamics, cell culture, microfluidics, rheology, chemistry of polymers and hydrogels will be considered as an asset. A multidisciplinary background and interest are particularly valued. Depending on the candidate’s background and interests, the project can be oriented more towards the physical, chemical, or biological aspects.

Training period

The expected training period (4-6 month) will be from February/March to July/September 2026.

Contact

1 Dudaryeva et al., Tunable Bicontinuous Macroporous Cell Culture Scaffolds via Kinetically Controlled Phase Separation, Advanced Materials, 2025 ns l’interface d’édition: champ 'description' de la page Offre.