3D (bio)printing

Development of 3D (bio)printing processes for in-vitro models and monitoring tools

Bioprinting of a gut epithelium

Doctoral researcher: Elise Ponthier

Supervision: Laurent Malaquin / Arnaud Besson (CBI)

Associated Researchers : Julie Foncy, Daniel Ferri Angulo, Lucien Guth

We developed photosensitive biomaterials compatible with 3D printing allowing the adhesion and proliferation of intestinal cells. To do so, we combined polyethylene glycol diacrylate and gelatin methacrylate. We succeeded in printing 3D intestinal scaffolds by using high-resolution stereolithography after setting up a method to properly select printing parameters for our biomaterials. On these 3D scaffolds, we successfully achieved colonization of Caco-2 cells. We are currently working on seeding intestinal organoids on these scaffolds to reproduce the intestinal epithelium. These 3D scaffolds are the first brick in a more complex system designed to recreate the intestinal microenvironment.

Fundings: INCA, Fondation Toulouse Cancer Santé, Région Occitanie

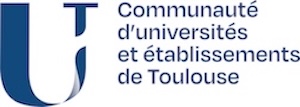

Two photon polymerization of mechanical metamaterials

Doctoral researcher: Ianis Drobecq

Supervision: Bastien Venzac / Laurent Malaquin

Associated researchers : Alexis Arcas

The extra-cellular matrix (ECM) is a biological environment composed mainly of collagen fibers, which forms a tissue in symbiosis with our cells. The ECM is essential to the survival and development of our cells (e.g. fibroblast, adipocyte). In connective tissues, certain pathologies influence its mechanical and structural properties through a mechanism that is still poorly understood. To gain a better understanding of cell-ECM interactions, we are developing fibrillar structures (scaffolds) micro-fabricated by two-photon 3D printing. Thanks to this technology, we can precisely control the dimensions of the scaffolds and hence their mechanical properties. Once characterized, these artificial structures are able to host fibroblasts, enabling us to study their behavior as a function of scaffold properties. In this way, we can propose artificial ECM models that can be customized for physiological and/or pathological environments.

Fundings: ANR Nanumat, ANR Printiss

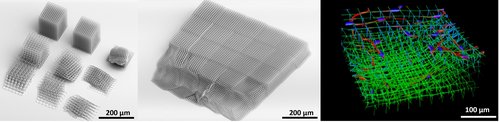

Gut fibroblasts in 2PP scaffolds

Doctoral researcher: Alexis Arcas

Supervisor: Bastien Venzac / Audrey Ferrand (IRSD)

In the EliA team, we are developing a new generation of artificial models of the extracellular matrix (ECM), using a high-resolution 3D printing technique (Nanoscribe). The development of these new models will enable us to understand in greater detail the contribution of the ECM's µ-architecture to the dynamics of Crohn's disease, which could open up new therapeutic avenues. Indeed, it has been shown that during an inflammatory phase, fibroblasts, which are the cells specializing in the secretion and remodeling of the ECM in vivo, are activated. Activation of the fibroblasts densifies the ECM, accentuating the inflammation. To now we have succeeded in printing 3D structures of controlled dimensions. On these 3D scaffolds, we successfully achieved colonization of fibroblasts (CCD18-Co). We are currently working on the influence of artificial matrix parameters on cell behaviour and morphology.

Fundings: ANR Nanumat

3D printing of glass AFM microfluidic probes

Doctoral researcher: Koutayba Saada

Supervisor: Laurent Malaquin, Etienne Dague

We aim to develop new fabrication processes incorporating 3D printing and selective laser machining technologies to create MEMS-based devices for the mechanical characterization of biological entities.

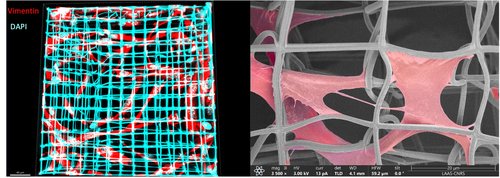

Multimaterial bio-printer based on microfluidic probes

Doctoral researcher: Victor Fournié

Supervisors: Laurent Malaquin, Emmanuelle Trévisiol, Pierre Joseph

Associated researchers : Sandrine Assié Souleille, Julie Foncy

Description of the project : We developped 3D-FlowPrint concept, a novel approach combining microfluidics and laser lithography to address the challenge of multimaterial, high-resolution 3D printing. By integrating an opto-microfluidic printhead in a liquid medium, we ensure precise material delivery through hydrodynamic confinement, avoiding cross-contamination. This unique system separates material delivery from polymerization, enabling resolutions as fine as 10 μm and rapid material switching within 60 seconds. Our proof-of-concept demonstrates the fabrication of complex 2D and 3D heterogeneous structures using PEGDA-based hydrogels. 3D-FlowPrint offers unprecedented capabilities for creating sub-millimetric multimaterial designs. We validated its potential by engineering microenvironments for cell culture applications.

Publications:

Fundings : ANR Printiss

Stereolithography for microfluidic chips

Researcher: Bastien Venzac

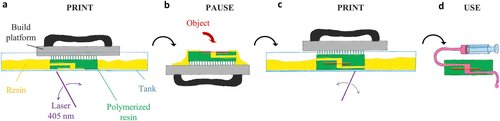

Light-based 3D printing, and in particular stereolithography, is more and more used for the fabrication of microfluidics chips for biological applications. Working first on the post-treatment of 3D-printing moulds for PDMS replication, I am moving toward the direct printing of microfluidic and organ-on-chip systems. I'm now studying the biocompatibility and the post-treatments of resin-based microfluidic chips. I am also developing new processes to add functionalities into 3D printed chips using a print-pause-print integration, to insert imaging windows, porous or elastic membranes, dried reagents, etc...

Collaborations: Séverine Le Gac (Twente University), Marie Saint Dizier and Karine Reynaud (INRAE Tours)

Publications:

- Venzac, Bastien, et al. "PDMS curing inhibition on 3D-printed molds: why? Also, how to avoid it?." Analytical chemistry 93.19 (2021): 7180-7187.

- Sagot, Matthieu, et al. "Functionality integration in stereolithography 3D printed microfluidics using a “print-pause-print” strategy." Lab on a Chip 24.14 (2024): 3508-3520.